Доклад про сварку на английском

Welding is the process of joining together pieces of metal or metallic parts by bringing them into intimate proximity and heating the places of contact to a state of fusion or plasticity. This leads to interpenetration of the atoms of the metals in the weld zone, and a strong inseparable joint is formed after the metals have cooled.

Welding finds widespread application in almost all branches of industry and construction. Welding is extensively employed in the fabrication and erection of steel structures in industrial construction and civil engineering (frames of industrial buildings, bridges, etc.), vessels of welded - plate construction (steel reservoirs, pipelines, etc.) and concrete reinforcement.

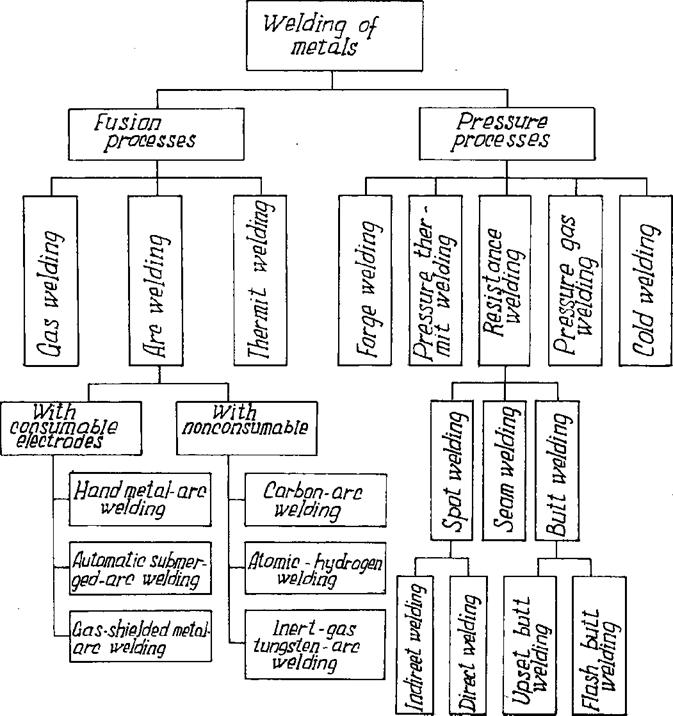

Welding processes may be classified according to the source of energy employed for heating the metals and the state of the metal at the place being welded. A master chart of the principal welding processes is shown on the next page.

In fusion welding the welding area is heated by a concentrated source of heat to a molten state and filler metal must be added to the weld. In accordance with the method applied for feeding the filler metal to the weld, welding procedures are classified as manual, semi-automatic or automatic welding.

Pressure welding processes involve the heating of the metallic parts only to a plastic or lightly fused state and forcing them together with external pressure. Pressure welding processes are applied to metals which are capable of being brought to a plastic state by heating or due to the action of external forces. It has been established that in this process the most weldable metals prove to be those metals which have higher thermal conductivity. Such metals more rapidly dissipate heat from the weld zone and do not allow an excessively high temperature to be concentrated in a small area (the latter may lead to considerable internal stress).

The quality of the joint obtained in pressure welding depends to a great extent upon the magnitude of the applied pressure and the temperature to which the metal is heated at the moment of welding. The higher this temperature, the less unit pressure will be required to produce the weld. Proper cleaning of the surface to be joined is one of the main conditions for obtaining high-quality welds in pressure-welding procedures.

Master Chart of the Principal Welding Processes

Find equivalents in the text for the following word combinations:

Welding is widely used, welded area, disperse heat, parts made of steel, designing and producing metal structures, pressing together.

Translate the following sentences from Russian into English using the information from the text:

1. Взаимопроникновение атомов металлических изделий под действием высокой температуры и давления приводит к образованию сварного соединения.

2. Сварка находит широкое применение во всех отраслях промышленности и в строительстве.

3. При сварке давлением лучше свариваются металлы с большей теплопроводностью, а необходимым условием получения высококачественного соединения является предварительная очистка свариваемых поверхностей.

4. При сварке плавлением используется присадочный металл, подача которого может осуществляться автоматически.

5. Чем ниже температура нагрева металла, тем выше необходимое для получения соединения давление.

6. Изготовление и монтаж стальных конструкций невозможны без применения сварки.

7. Сварка широко применяется в строительстве для создания каркаса зданий.

8. По типу подачи присадочного материала сварочные процессы делятся на ручные и механизированные.

9. Концентрация высоких температур на малых участках (неравномерность нагрева) приводит к появлению внутреннего напряжения в металлах.

10. Свариваемые детали должны находиться в непосредственной близости друг от друга.

Use the information of the Master Chart of welding processes above to complete the following sentences:

1. The two basic welding processes are. .

2. The fusion processes consist of. .

3. Among these, arc welding can be accomplished .

4. Arc welding with consumable electrodes includes the following types. .

5. Carbon arc welding, atomic hydrogen welding, inert gas tungsten arc welding refer to. .

6. The pressure processes include. .

7. Resistance welding is divided into three types . .

Translate the following text from Russian into English:

CBapKa - это процесс получения неразъёмного соединения деталей машин, конструкций и сооружений посредством местного разогрева (вплоть до плавления), пластической деформации или при совместном действии того и другого; суть сварки заключается в таком взаимном проникновении или сближении поверхностей свариваемых тел, при котором в месте соединения начинают действовать силы межатомного (межмолекулярного) сцепления. Различают сварку плавлением (дуговая, газовая, плазменная, электроннолучевая, лазерная) и сварку давлением (контактная, конденсаторная, холодная, ультразвуковая, термокомпрессионная, диффузионная). Выбор того или иного способа сварки зависит от физико-химических свойств свариваемых материалов, условий проведения сварки, от толщины соединяемых деталей и конструкции соединений.

Remember all the welding types which you have read about before and make a complete list of these types.

Think and say: What can be the difference between the principle (“traditional”) and alternative types of welding? Why are traditional welding processes not sufficient?

Настоящее пособие предназначено для студентов 3-5 курсов английского переводческого отделения, специализирующихся в переводе текстов по сварочному производству.

В связи с отсутствием доступных англо-русских словарей по сварке каждый текст снабжен списком основных терминов и словосочетаний. В ходе работы над английским текстом студенты выполняют ряд упражнений, направленных на активизацию новых для них технических понятий и подготовку к переводу. Упражнения частично проверяются в аудитории. Упражнения на поиск в тексте соответствий, синонимов, расшифровку сокращений и др. снимают первоначальные трудности при работе с незнакомой для студентов сферой деятельности. Когда у студентов накоплен достаточный словарный запас, он выполняют также перевод несложных текстов с русского языка. Эти тексты обычно связаны с теми же аспектами сварочного производства, которые были рассмотрены при переводе с английского, однако не являются их обратным переводом..

На старших курсах возрастает сложность переводимых текстов, сокращается количество вспомогательных упражнений..

Для контроля усвоения терминов разработана система тестовых заданий.

1. Welding and cutting ……………………………………..

2. Gas tungsten arc welding………………………………..

4. Submerged arc welding…………………………………..

6. Shielded metal arc welding……………………………….

7. SMA welding equipment…………………………………

9. Gas metal arc welding…………………………………….

4. Oxy-fuel welding and cutting……………………….

5. Electron beam welding………………………………

6. Laser beam welding…………………………………

7. Resistance welding………………………………….

15. Welding defects

16. Avoiding welding defects

17. Detection of welding defects

18. Spot welding

19. Oxy-gas torches (regulators)

20. Gas hoses and valves

21. Fuels in oxy-fuel welding

22. Hazards in oxy-fuel welding

23. Oxy-acetylene welding (pre-heating)

24. Torch practice

25. Welding ferrous metals

26. Welding non-ferrous metals

27. Cold welding

28. General requirements for steel fabrication

29. Repairs, inspection and tolerances

30. Fundamentals of resistance method

31. Applications of resistance method

32. Troubles and remedies

33. Electric arc welding

36. Thermit welding

37. Requirements for welding hulls

38. Types of connections and preparation

39. Types of welding in making hulls

40. Workmanship in making hulls

41. Modifications, repairs and testing during construction

42. Special requirements

43. Weld testing

44. Personnel requirements

45. Welding procedure characteristics

46. Safety precautions in ship building

47. Oxy-acetylene welding equipment

48. Oxygen and its production

49. Arc welding equipment accessories

50. Gas metal arc welding equipment

51. Electrodes and their use

52. Tungsten electrodes

53. Electrodes and their use in AC/DC welding

54. Сварные соединения и швы

55. Подготовка деталей к сварке

56. Газовая сварка

57. Контактная точечная сварка

58. Дефекты сварки

59. Автоматическая дуговая сварка

60. Дуговые автоматы

61. Сварочные флюсы

62. Защитные газы

63. Сварочные горелки

Text 1. WELDING AND CUTTING

Welding is the most common way of permanently joining metal parts. In this process heat is applied to metal pieces, melting and fusing them to form a permanent bond. Because of its strength, welding is used in shipbuilding, automobile manufacturing and repair, aerospace applications, and thousands of other manufacturing activities. Welding is used to join beams when constructing buildings, bridges and other structures, to join pipes in pipelines, power plants, and refineries.

Welders use many types of welding equipment set up in a variety of positions, such as flat, vertical, horizontal and overhead. They may perform manual welding, in which the work is entirely controlled by the welder, or semiautomatic welding, in which the welder uses machinery, such as a wire feeder, to perform welding tasks.

There are about 100 different types of welding. Arc welding is the most common type. Standard arc welding involves two large alligator clips that carry a strong electrical current. One clip is attached to any part of the workpiece being welded. The second clip is connected to a thin welding rod. When the rod touches the workpiece, a powerful electrical circuit is created. The massive heat produced by the electrical current causes both the workpiece and the steel core of the rod to melt together, cooling quickly to form a solid bond. During welding, the flux that surrounds the rod’s core, vaporizes, forming an inert gas, that serves to protect the weld from atmospheric elements that might weaken it. Welding speed is important. Variations in speed can change the amount of flux applied, weakening the weld, or weakening the surrounding metal by increasing heat exposure.

Two common but advanced types of arc welding are Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding. TIG welding is often used with stainless steel or aluminum. While TIG uses welding rods, MIG uses a spool of continuously fed wire, which allows the welder to join longer stretches of metal without stopping to replace the rod. In TIG welding, the welder holds the welding rod in one hand and an electric torch in the other hand. The torch is used to simultaneously melt the rod and the workpiece. In MIG welding the welder holds the wire feeder, which functions like the alligator clip in arc welding. Instead of using gas flux surrounding the rod, TIG and MIG protect the initial weld from the environment by blowing inert gas onto the weld.

Like arc welding, soldering and brazing use molten metal to join two pieces of metal. However, the metal added during the process has a melting point lower than that of the work-piece, so only the added metal is melted, not the work-piece. Soldering uses metals with a melting point below 800º F (about 426ºC); brazing uses metals with a higher melting point. Because soldering and brazing do not melt the work-piece, these processes normally do not create the distortions or weaknesses in the work-piece that can occur with welding. Soldering is commonly used to join electrical, electronic and other small metal parts. Brazing produces a stronger joint than soldering does, and it is often used to join metals other than steel, such as brass. Brazing can also be used to apply coating to parts to reduce wear and protect against corrosion.

Skilled welding, soldering and brazing workers usually plan work from drawings or specifications or use their knowledge of fluxes and base metals to analyze the parts to be joined. These workers can select and set up welding equipment, execute the planned welds, and examine welds to ensure that they meet standards or specifications. They are even examining the weld while they are welding. By observing problems with the weld, they compensate by adjusting the speed, voltage, amperage, or feed of the rod. Highly skilled welders are often trained to work with a wide variety of materials in addition to steel, such as titanium, aluminum, or plastics. Some welders have more limited duties, however. They perform routine jobs that already have been planned and laid out and do not require extensive knowledge of welding techniques.

Automated welding is used in an increasing number of production processes. In these instances, a machine or robot performs welding tasks while monitored by a welding machine operator. Welding, soldering and brazing machine setters, operators, and tenders follow specified layouts, work orders or blueprints. Operators must load parts correctly and constantly monitor the machine to ensure that it produces the desired bond.

The work of arc, plasma and oxy-gas cutters is closely related to that of welders. However, instead of joining metals, cutters use heat from an electric arc, a stream of ionized gas (plasma), or burning gases to cut and trim metal objects to specific dimensions. Cutters also dismantle large objects, such as ships, railroad cars, automobiles, buildings, or aircraft. Some operate and monitor cutting machines similar to those used by welding machine operators. Plasma cutting has been increasing in popularity because, unlike other methods, it can cut a wide variety of metals, including stainless steel, aluminum, and titanium.

Welding, soldering and brazing workers are often exposed to a number of hazards, including the intense light created by the arc, poisonous fumes, and very hot materials. They wear safety shoes, goggles, hoods with protective lenses and other devices designed to prevent burns and eye injuries and to protect them from falling objects. They normally work in well-ventilated areas to limit their exposure to fumes. Automated welding, soldering and brazing machine operators are not exposed to as many dangers, however, and a face shield or goggles usually provide adequate protection for these workers.

VOCABULARY

weld – (сварной) шов

to weld – сваривать, варить

to melt – плавить(ся)

to fuse – сплавлять(ся)

to form a solid bond – образовать прочное\сплошное соединение

workpiece – (обрабатываемое) изделие

arc welding – дуговая сварка

electrical current - электрический ток

welding rod – электрод, стержень

Tungsten Inert Gas Welding (TIG) – сварка вольфрамовым электродом в инертном газе

Metal Inert Gas Welding (MIG) – сварка металлическим электродом в инертном газе

heat exposure - воздействие высоких температур, тепла

electric torch – сварочная горелка

gas flux welding - сварка под флюсом

soldering – пайка (мягким припоем)

brazing – пайка (твердым припоем)

molten metal – расплав, расплавленный металл

melting point – точка \ температура плавления

to apply coating – нанести покрытие

to reduce wear – уменьшить износ

specifications – технические условия, спецификация

base metal - основной металл

amperage – сила тока

automated welding – автоматическая сварка

to monitor – наблюдать, контролировать

machine setter - наладчик

machine tender – механик, оператор

specified – соответствующий техническим условиям

work order – наряд (на выполнение работы)

arc\plasma\oxy-gas cutter – дуговой\плазменный\кислородный резак

cutter – резчик, резак

burning gas – горючий газ

to trim – доводить, выравнивать, снимать заусенцы

to dismantle – разбирать, демонтировать

safety shoes – защитная обувь

protective lenses – защитные стекла

Упражнения

I. Найдите в тексте английские эквиваленты следующих слов и словосочетаний:

1. Потолочное положение, 2. дуговая сварка, 3. благодаря своей прочности, 4. стержень электрода, 5. нержавеющая сталь, 6. электрогорелка, 7. температура плавления, 8. наносить покрытие, 9. уменьшить износ, 10. устанавливать\на-лаживать сварочное оборудование, 11. отвечать техническим условиям, 12. ручная сварка, 13. обрабатываемое изделие, 14. подача электрода, 15. квалифицированный сварщик, 16. размечать, наносить разметку, 17. кислородный резак, 18. демонтировать, разбирать, 19. защитные очки, 20. снимать заусенцы, выравнивать.

II. Переведите на РЯ следующие слова и выражения:

1. To adjust the amperage, 2. routine job, 3. circuit, 4. heat exposure, 5. to fuse, 6. welding rod, 7. to form a permanent bond, 8. beam, 9. alligator clip, 10. massive heat, 11. TIG, 12. MIG, 13. to meet standards, 14. overhead position, 15. specifications, 16. welding technique, 17. to monitor, 18. soldering, 19. machine setter, 20. electrical current.

Ш.Охарактеризуйте различие в семантике следующих синонимов:

To melt – to fuse, constant – steady – stable, strength – force – power, standard – normal – usual, clip – clamp, welding rod – electrode, soldering – brazing, technique – technology, to join – to weld – to bind. MIG – TIG, hazard – dander, fume – smoke.

Text 2. GAS TUNGSTEN ARC WELDING

Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas welding (TIG), is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by a shielding gas (usually an inert gas such as argon), and a filler metal is normally used, though some welds, known as autogenous welds, do not require it. A constant-current welding power supply produces energy which is conducted across the arc through a column of highly ionized gas and metal vapours known as plasma.

GTAW is most commonly used to weld thin sections of stainless steel and light metals such as aluminum, magnesium, and copper alloys. The process grants the operator greater control over the weld than competing procedures such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quality welds. However, GTAW is comparatively more complex and difficult to master, and furthermore, it is significantly slower than most other welding techniques. A related process, plasma arc welding, uses a slightly different welding torch to create a more focused welding arc and as a result it is often automated.

After the discovery of arc in 1800, arc welding developed slowly. C.L.Coffin had the idea of welding in an inert gas atmosphere in 1890, but even in the early 1900-s welding non-ferrous materials like aluminum and magnesium remained difficult, because these metals reacted rapidly with the air, resulting in porous and dross-filled welds. Processes using flux covered electrodes did not satisfactorily protect the weld area from contamination. To solve the problem, bottled inert gases were used in the beginning of the 1930-s. A few years later, a direct current gas-shielded welding process emerged in the aircraft industry for welding magnesium. The process was perfected in 1941 and became known as heliarc or tungsten inert gas welding, because it utilized a tungsten electrode and helium as a shielding gas. Initially, the electrode overheated quickly, and in spite of tungsten’s high melting temperature, particles of tungsten were transferred to the weld. To address the problem the polarity of the electrode was changed from positive to negative, but this made it unsuitable for welding many non-ferrous materials. Finally, the development of alternating current units made it possible to stabilize the arc and produce high quality aluminum and magnesium welds.

In 1953, a new process based on GTAW was developed, called plasma arc welding. It affords greater control and improves weld quality by using a nozzle to focus the electric arc, but it is largely limited to automated systems, whereas GTAW remains primarily a manual, hand-held method. Development within the GTAW process has continued as well, and today a number of variations exist.

For GTA welding of carbon and stainless steels, the selection of a filler material is important to prevent excessive porosity. Oxides on the filler material and workpieces must be removed before welding to prevent contamination, and immediately prior to welding, alcohol or acetone should be used to clean the surface. Preheating is generally not necessary for mild steels less than one inch thick, but low alloy steels may require preheating to slow the cooling process and prevent the formation of martensite in the heat-affected zone. Tool steels should also be preheated to prevent cracking in the heat-affected zone. Austenitic stainless steels do not require preheating, but martensitic and ferritic chromium stainless steels do. A DCEN power source is normally used, and thoriated electrodes, tapered to a sharp point, are recommended. Pure argon is used for thin workpieces, but helium can be introduced as thickness increases.

TIG welding of copper and some of its alloys is possible, but in order to get a weld free of oxidation and porosities, shielding gas needs to be provided on the root side of the weld. Alternatively, a special backing tape, consisting of a fiberglass weave on heat-resistant aluminum tape can be used, to prevent air reaching the molten metal.

Welding dissimilar metals often introduces new difficulties to GTA welding, because most materials do not easily fuse to form a strong bond. However, welds of dissimilar materials have numerous applications in manufacturing, repair work and the prevention of corrosion and oxidation. In some joints, a compatible filler material is chosen to help form the bond, and this filler metal can be the same as one of the base materials (for example, using a stainless steel filler metal with stainless steel and carbon steel as base materials), or a different metal (such as the use of a nickel filler metal for joining steel and cast iron). Very different materials may be coated with a material compatible with a particular filler material, and then welded. In addition, GTAW can be used in cladding or overlaying dissimilar materials.

When welding dissimilar metals, the joint must have an accurate fit, with proper gap dimensions and bevel angles. Care should be taken to avoid excessive melting base material. Pulsed current is particularly useful for those applications, as it helps limit the heat input. The filler metal should be added quickly, and a large weld pool should be avoided to prevent dilution of the base material.

VOCABULARY

Gas tungsten arc welding (GRAW) – сварка вольфрамовым углеродом в

TIG – tungsten inert gas welding - сварка вольфрамовым электродом в среде

- Для учеников 1-11 классов и дошкольников

- Бесплатные сертификаты учителям и участникам

Описание презентации по отдельным слайдам:

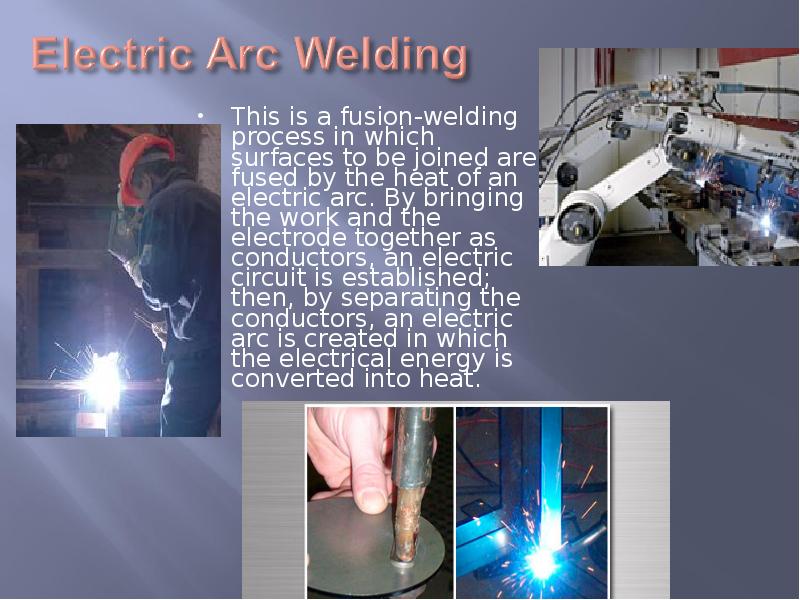

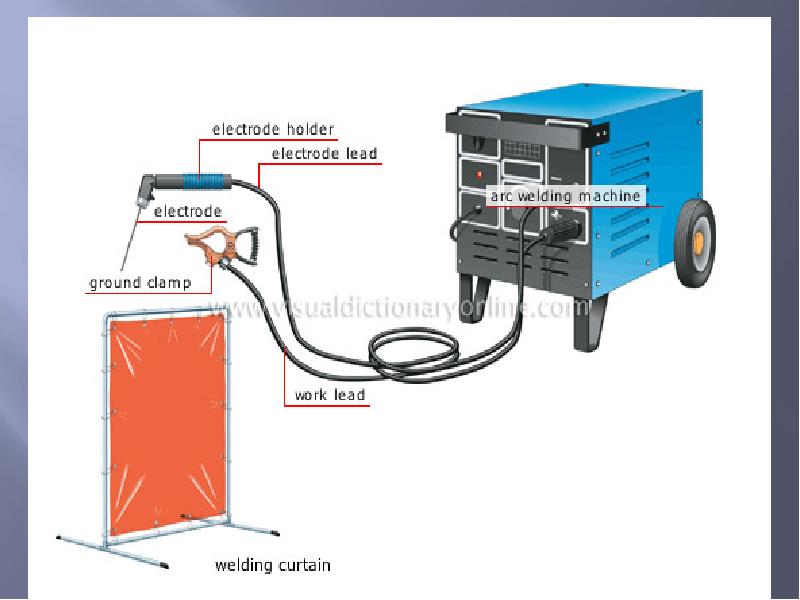

Thermal class Arc welding is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. They can use either direct or alternating current, and consumable or non-consumable electrodes. The welding region is usually protected by some type of shielding gas, vapor, or slag. Arc welding processes may be manual, semi-automatic, or fully automated vehicles. Diagram of arc and weld area, in shielded metal arc welding 1. Coating Flow 2. Rod 3. Shield Gas 4. Fusion 5. Base metal 6. Weld metal 7. Solidified Slag Diagram of arc and weld area, in shielded metal arc welding

Laser Welding (LW) is a welding process, in which heat is generated by a high energy laser beam targeted on the work piece. The laser beam heats and melts the work pieces edges, forming a joint.

Thermite Welding is a welding process utilizing heat generated by exothermic chemical reaction between the components of the thermite (a mixture of a metal oxide and aluminum powder). The molten metal, produced by the reaction, acts as a filler material joining the work pieces after Solidification.

Electroslag Welding is a welding process, in which the heat is generated by an electric current passing between the consumable electrode and the work piece through a molten slag covering the weld surface. Prior to welding the gap between the two work pieces is filled with a welding flux. Electro-slag Welding is initiated by an arc between the electrode and the work piece (or starting plate). Heat, generated by the arc, melts the fluxing powder and forms molten slag. The slag, having low electric conductivity, is maintained in liquid state due to heat produced by the electric current.

Plasma Arc Welding is the welding process utilizing heat generated by a constricted arc struck between a tungsten non-consumable electrode and either the work piece (transferred arc process) or water cooled constricting nozzle (non-transferred arc process).

Electron Beam Welding is a welding process utilizing a heat generated by a beam of high energy electrons. The electrons strike the work piece and their kinetic energy converts into thermal energy heating the metal so that the edges of work piece are fused and joined together forming a weld after Solidification.

Resistance Welding is a welding process, in which work pieces are welded due to a combination of a pressure applied to them and a localized heat generated by a high electric current flowing through the contact area of the weld. Thermo-mechanical class

Diffusion Welding is a Solid State Welding process, in which pressure applied to two work pieces with carefully cleaned surfaces and at an elevated temperature below the melting point of the metals. Bonding of the materials is a result of mutual diffusion of their interface atoms. Advantages of Diffusion Welding: Dissimilar materials may be welded; Welds of high quality are obtained; No limitation in the work pieces thickness. Disadvantages of Diffusion Welding: Time consuming process with low productivity; Very thorough surface preparation is required prior to welding process; The mating surfaces must be precisely fitted to each other;

Forge Welding is a Solid State Welding process, in which low carbon steel parts are heated to about 1800°F (1000°C) and then forged (hammered). Prior to Forge Welding, the parts are scarfed in order to prevent entrapment of oxides in the joint. Forge Welding is used in general blacksmith shops and for manufacturing metal art pieces and welded tubes.

Mechanical class Friction Welding is a Solid State Welding process, in which two cylindrical parts are brought in contact by a friction pressure when one of them rotates. Friction between the parts results in heating their ends. Forge pressure is then applied to the pieces providing formation of the joint.

Ultrasonic Welding is a Solid State Welding process, in which two work pieces are bonded as a result of a pressure exerted to the welded parts combined with application of high frequency acoustic vibration. Advantages of Ultrasonic Welding: Dissimilar metals may be joined; Very low deformation of the work pieces surfaces; The process may be integrated into automated production lines; Moderate operator skill level is enough. Disadvantages of Ultrasonic Welding: Only small and thin parts may be welded; Work pieces and equipment components may fatigue at the reciprocating loads provided by ultrasonic vibration; Work pieces may bond to the anvil.

Explosive Welding is a Solid State Welding process, in which welded parts (plates) are metallurgically bonded as a result of oblique impact pressure exerted on them by a controlled detonation of an explosive charge. Advantages of Explosive Welding Large surfaces may be welded; Low cost and simple process; Surface preparation is not required. Disadvantages of Explosive Welding: Brittle materials cannot be processed; Only simple shape parts may be bonded: plates, cylinders; Thickness of flyer plate is limited - less than 2.5” (63 mm); Safety and security aspects of storage and using explosives.

Cold Welding is a Solid State Welding process, in which two work pieces are joined together at room temperature and under a pressure, causing a substantial deformation of the welded parts and providing an intimate contact between the welded surfaces. As a result of the deformation, the oxide film covering the welded parts breaks up, and clean metal surfaces reveal. Intimate contact between these pure surfaces provide a strong and defectless bonding. Aluminum alloys, Copper alloys, low carbon steels, Nickel alloys, and other ductile metals may be welded by Cold Welding. Cold Welding is widely used for manufacturing bi-metal steel - aluminum alloy strips, for cladding of aluminum alloy strips by other aluminum alloys or pure aluminum. Bi-metal strips are produced by Rolling technology. Presses are also used for Cold Welding.

Вы можете изучить и скачать доклад-презентацию на тему Welding. Презентация на заданную тему содержит 21 слайдов. Для просмотра воспользуйтесь проигрывателем, если материал оказался полезным для Вас - поделитесь им с друзьями с помощью социальных кнопок и добавьте наш сайт презентаций в закладки!

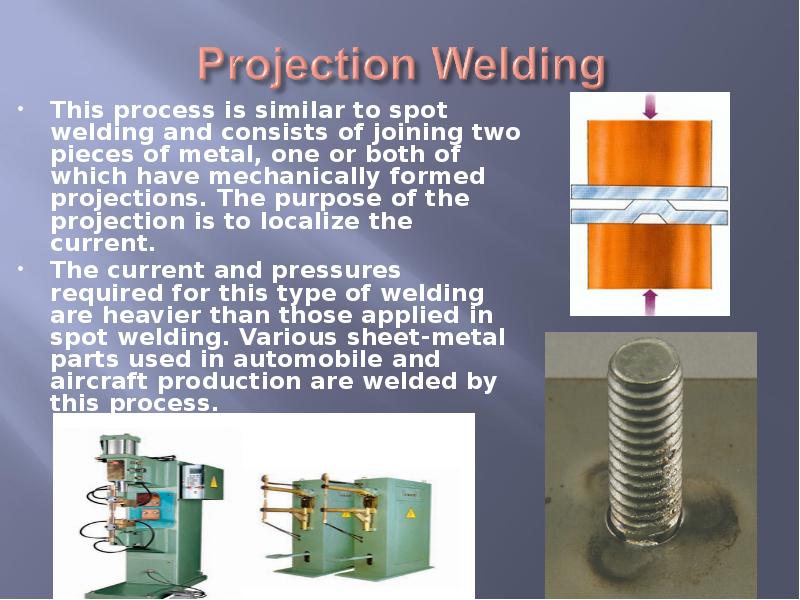

1.Welding 1.Welding 2. Forge or Blacksmith Welding 3. Thermit Welding 4. Electric Welding 5. Types of resistance welding: -Spot Welding; - Butt Welding; -Flash Welding; - Percussion Welding; -Seam Welding; -Projection Welding; - Electric Arc Welding

The temperature of the molten metal is high enough to fuse the broken sections, thus forming a homogeneous mass of metal. The equipment for thermit welding is simple and inexpensive but the quality of the weld is not such as to recommend it for extensive use. The process can be used only on low carbon steels and wrought iron. The temperature of the molten metal is high enough to fuse the broken sections, thus forming a homogeneous mass of metal. The equipment for thermit welding is simple and inexpensive but the quality of the weld is not such as to recommend it for extensive use. The process can be used only on low carbon steels and wrought iron.

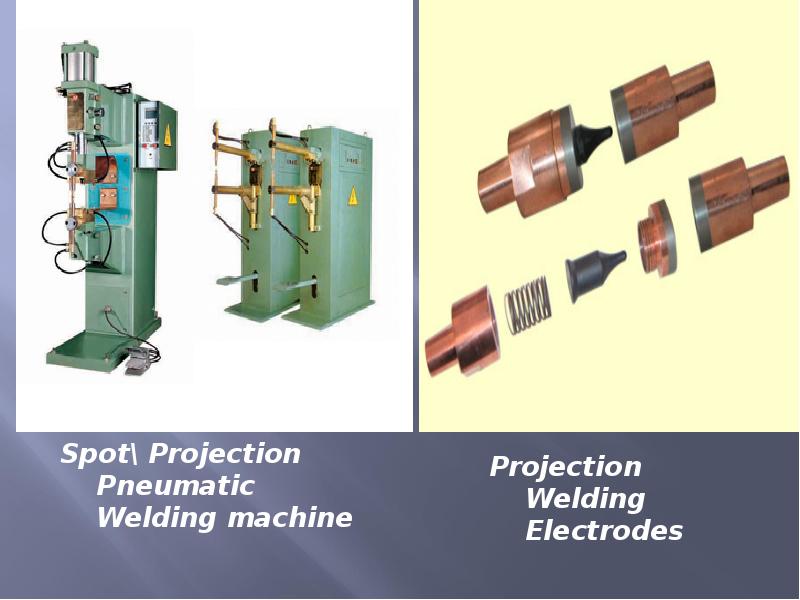

This type of welding is a pressure process, as is forge welding. It consists of heating to their plastic temperature the surfaces of parts to be joined, then applying pressure mechanically to achieve complete union of the parts. The heating is accomplished by passage of a heavy, localized electric current. Alternating current of common commercial voltage is employed for this purpose. In all types of resistance welding, selection of proper electrodes is important to the success of the process. Electrodes must possess a high degree of thermal and electrical conductivity and they also must possess strength and hardness. This type of welding is a pressure process, as is forge welding. It consists of heating to their plastic temperature the surfaces of parts to be joined, then applying pressure mechanically to achieve complete union of the parts. The heating is accomplished by passage of a heavy, localized electric current. Alternating current of common commercial voltage is employed for this purpose. In all types of resistance welding, selection of proper electrodes is important to the success of the process. Electrodes must possess a high degree of thermal and electrical conductivity and they also must possess strength and hardness.

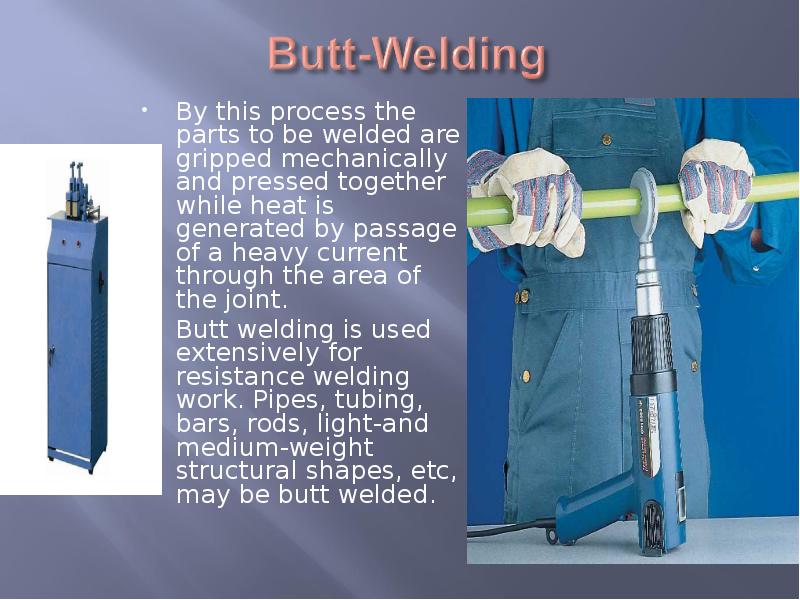

By this process the parts to be welded are gripped mechanically and pressed together while heat is generated by passage of a heavy current through the area of the joint. By this process the parts to be welded are gripped mechanically and pressed together while heat is generated by passage of a heavy current through the area of the joint. Butt welding is used extensively for resistance welding work. Pipes, tubing, bars, rods, light-and medium-weight structural shapes, etc, may be butt welded.

This is another type of butt welding, the difference consisting in the method of heating the base metals. The electrodes are clamped to the parts to be joined, and a heavy current is passed through them. The movable electrode brings the surface of the metal it holds into contact with the surface of the metal held in the stationary electrode. Just before the two pieces meet, an arc developed in the short gap causes sufficient heat to make the surface to be joined plastic. This is another type of butt welding, the difference consisting in the method of heating the base metals. The electrodes are clamped to the parts to be joined, and a heavy current is passed through them. The movable electrode brings the surface of the metal it holds into contact with the surface of the metal held in the stationary electrode. Just before the two pieces meet, an arc developed in the short gap causes sufficient heat to make the surface to be joined plastic.

This process is similar to flash welding inasmuch as it relies upon a sudden discharge of electrical energy (produced by the arc) at the joint to generate sufficient heat to make the surfaces to be joined plastic. The pressure required to accomplish the weld at the proper moment is obtained by employing a heavy spring. This process is similar to flash welding inasmuch as it relies upon a sudden discharge of electrical energy (produced by the arc) at the joint to generate sufficient heat to make the surfaces to be joined plastic. The pressure required to accomplish the weld at the proper moment is obtained by employing a heavy spring.

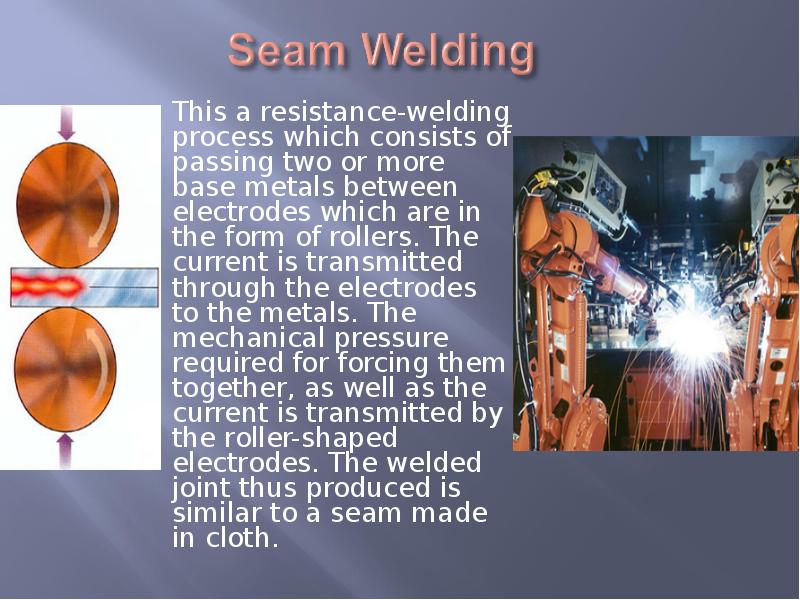

This a resistance-welding process which consists of passing two or more base metals between electrodes which are in the form of rollers. The current is transmitted through the electrodes to the metals. The mechanical pressure required for forcing them together, as well as the current is transmitted by the roller-shaped electrodes. The welded joint thus produced is similar to a seam made in cloth. This a resistance-welding process which consists of passing two or more base metals between electrodes which are in the form of rollers. The current is transmitted through the electrodes to the metals. The mechanical pressure required for forcing them together, as well as the current is transmitted by the roller-shaped electrodes. The welded joint thus produced is similar to a seam made in cloth.

Читайте также: